The integration of computer vision in manufacturing is reshaping the industry by enhancing efficiency, precision, and productivity. This cutting-edge technology enables machines to interpret and understand the visual world, mimicking the capability of human vision. As a result, manufacturers can achieve unprecedented levels of automation and quality control.

What is Computer Vision?

Computer vision is a field of artificial intelligence (AI) that trains computers to interpret and make decisions based on visual data from the world. This technology is utilized to automate tasks that require visual perception, such as identifying defects on a production line or sorting products by type and quality.

Importance of Computer Vision in Manufacturing

The application of computer vision in manufacturing is crucial for several reasons. It reduces the reliance on human inspection, which can be error-prone and inconsistent. Moreover, it allows for 24/7 operation without fatigue, ensuring constant productivity and efficiency.

Enhancing Quality Control

Quality control is significantly improved with computer vision systems. These systems can detect defects and irregularities with a higher accuracy than the human eye, ensuring that only products meeting the highest standards reach the market.

Streamlining Production Processes

By employing computer vision, manufacturers can streamline their production processes. This technology enables real-time monitoring and analysis of the assembly line, facilitating quicker adjustments and optimizations. For more on how AI aids continuous improvement, visit continuous feedback in QA.

Applications of Computer Vision in Manufacturing

Automated Inspection Systems

Automated inspection systems in manufacturing use computer vision to inspect products for defects, ensuring that only high-quality goods are shipped to consumers. This reduces waste and increases customer satisfaction.

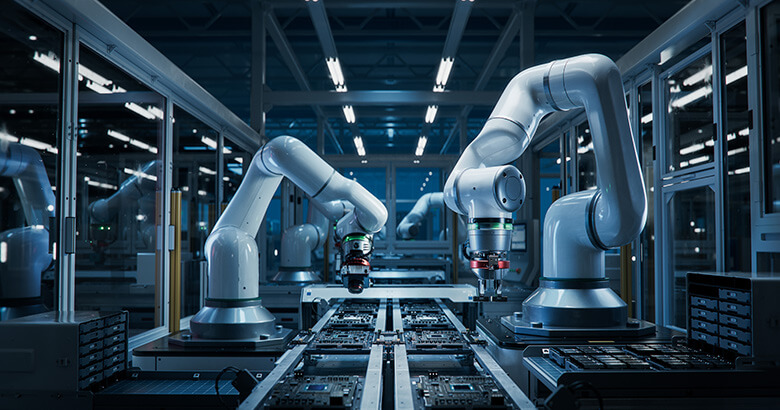

Robotics and Automation

Robots equipped with computer vision can perform complex tasks such as assembling intricate components or sorting items by size and color. This level of automation is enhancing the efficiency and flexibility of manufacturing operations.

Inventory Management

In inventory management, computer vision systems can track and manage stock levels, predict shortages, and streamline the supply chain. This technology allows for more accurate and efficient inventory control.

Challenges in Implementing Computer Vision

Despite its advantages, implementing computer vision in manufacturing poses challenges. These include the high cost of technology, integration with existing systems, and the need for skilled personnel. Overcoming these challenges requires strategic planning and investment.

Cost and Technological Barriers

The initial cost of implementing computer vision systems can be high, and the technology requires constant updates and maintenance to keep up with advancements. Manufacturers must weigh these costs against the long-term benefits.

Integration with Existing Systems

Integrating computer vision with existing manufacturing systems can be complex. It requires compatibility with current processes and the capacity to handle large volumes of data efficiently. For insights on how AI can optimize testing processes, see semantic analysis in testing.

The Future of Computer Vision in Manufacturing

The future of computer vision in manufacturing looks promising. As technology advances, the capabilities of computer vision systems will expand, offering even greater efficiency and accuracy. The integration of AI and machine learning will further enhance these systems, making them more intuitive and adaptable.

Trends to Watch

Emerging trends in computer vision include the use of deep learning algorithms and edge computing, which allow for faster processing and real-time decision-making. These technologies are set to revolutionize the manufacturing landscape.

Continuous Improvement and Innovation

Manufacturers are continually seeking ways to improve their processes. With computer vision, they can achieve a level of precision and efficiency that was previously unattainable, paving the way for new innovations and advancements in the industry.

Conclusion

In conclusion, the integration of computer vision in manufacturing is transforming the industry. Its ability to enhance quality control, streamline production, and improve inventory management is invaluable. Despite the challenges, the benefits far outweigh the drawbacks, making it a worthwhile investment for manufacturers looking to stay competitive in a rapidly evolving market.

FAQs

What industries benefit from computer vision in manufacturing?

Industries such as automotive, electronics, pharmaceuticals, and food and beverage benefit significantly from the implementation of computer vision for enhanced quality control and efficiency.

How does computer vision improve quality control?

Computer vision improves quality control by providing accurate and consistent inspection, detecting defects that might be missed by human inspectors, thus ensuring higher product standards.

What are the future prospects of computer vision in manufacturing?

The future prospects of computer vision in manufacturing are promising, with advancements in AI and machine learning expected to further enhance the capabilities and applications of this technology.

This article contains affiliate links. We may earn a commission at no extra cost to you.