The world of AI visual inspection is evolving rapidly, with significant advancements and promising trends shaping its future. As industries continue to prioritize quality assurance, the adoption of AI-driven visual inspection systems is becoming more widespread. This article explores the current market trends and future prospects of AI visual inspection, providing insights into how these technologies are transforming quality control processes across various sectors.

Understanding AI Visual Inspection

AI visual inspection involves the use of artificial intelligence and machine learning algorithms to automate the process of inspecting products and materials for defects. These systems utilize advanced imaging technologies, such as cameras and sensors, to capture detailed images and analyze them for anomalies. By leveraging AI, these systems can identify defects with high accuracy and speed, reducing the reliance on human inspectors and improving overall efficiency.

The Importance of AI in Quality Assurance

In today’s competitive market, maintaining high product quality is crucial for businesses to stay ahead. AI visual inspection systems offer several advantages over traditional inspection methods. They provide consistent and objective assessments, eliminating human biases and errors. Additionally, these systems can handle large volumes of inspections at a faster rate, ensuring timely identification of defects and reducing production downtime.

Current Market Trends

Increased Adoption Across Industries

The adoption of AI visual inspection is on the rise across various industries, including manufacturing, automotive, electronics, and healthcare. Companies are recognizing the benefits of AI-driven inspection systems in improving product quality, reducing costs, and enhancing customer satisfaction. As a result, we are witnessing a growing demand for these technologies, driving the expansion of the AI visual inspection market.

Integration with IoT and Cloud Technologies

One of the key trends in the AI visual inspection market is the integration of these systems with Internet of Things (IoT) and cloud technologies. By connecting inspection systems to IoT devices, businesses can gather real-time data and insights, enabling proactive decision-making. Cloud-based platforms also facilitate seamless data storage and sharing, enhancing collaboration and analysis capabilities. Learn more about cloud AI for inspection.

Advancements in Machine Learning Algorithms

Continuous advancements in machine learning algorithms are driving the evolution of AI visual inspection systems. These algorithms are becoming more sophisticated, enabling systems to accurately detect complex defects and adapt to changing inspection requirements. The use of deep learning techniques, such as convolutional neural networks (CNNs), is enhancing the precision and reliability of defect detection, further boosting the market growth.

Future Prospects

Expansion into New Sectors

As the capabilities of AI visual inspection systems continue to improve, we can expect their adoption to expand into new sectors. Industries such as agriculture, food and beverage, and pharmaceuticals are likely to leverage AI-driven inspection technologies to ensure the quality and safety of their products. This expansion will open up new opportunities for market growth and innovation.

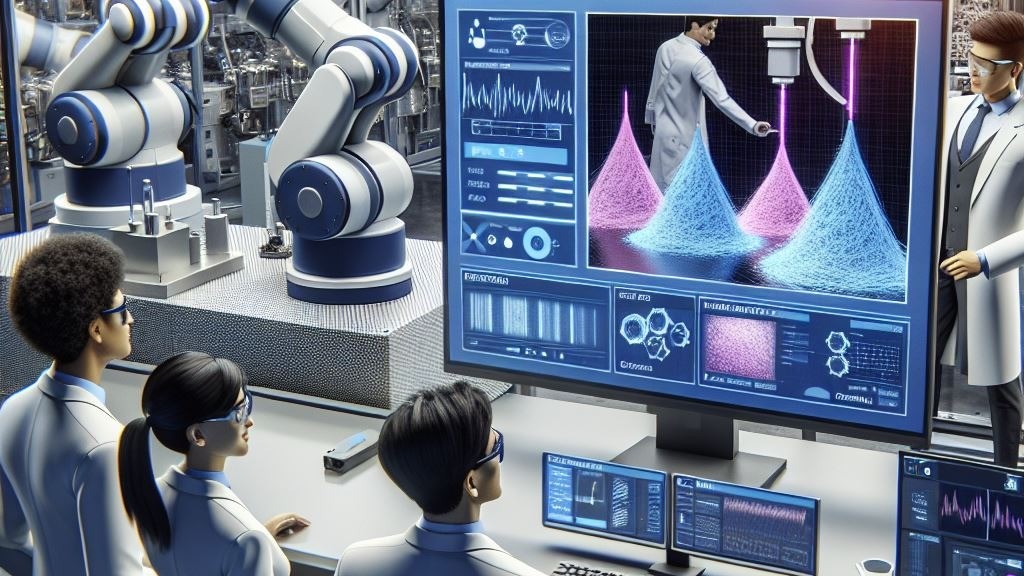

Enhanced Automation and Robotics Integration

The integration of AI visual inspection systems with automation and robotics is another promising prospect for the future. By combining these technologies, businesses can achieve fully automated and autonomous inspection processes, minimizing human intervention and maximizing efficiency. This integration will revolutionize industries by streamlining operations and reducing costs.

Focus on Reducing False Positives

Reducing false positives is a significant challenge in AI visual inspection. However, ongoing research and development efforts are focused on improving the accuracy of defect detection and minimizing false alarms. By refining algorithms and leveraging advanced data analytics, companies can enhance the reliability of inspection results, leading to more efficient quality control processes. Explore strategies for reducing false positives.

Conclusion

The AI visual inspection market is experiencing rapid growth and innovation, driven by the increasing demand for automated and accurate quality assurance solutions. As industries continue to embrace AI-driven inspection technologies, we can expect further advancements and expansion into new sectors. By leveraging the power of AI, businesses can achieve higher product quality, improved operational efficiency, and enhanced customer satisfaction. Stay informed about the latest trends and innovations in AI visual inspection to remain competitive in the evolving market landscape.

FAQs

What is AI visual inspection?

AI visual inspection involves the use of artificial intelligence to automate the process of inspecting products and materials for defects, improving accuracy and efficiency.

How does AI visual inspection benefit industries?

AI visual inspection offers consistent and objective assessments, reduces human errors, and handles large volumes of inspections at a faster rate, enhancing product quality and reducing costs.

What are the future prospects of AI visual inspection?

The future prospects of AI visual inspection include expansion into new sectors, integration with automation and robotics, and a focus on reducing false positives, driving innovation and market growth.

This article contains affiliate links. We may earn a commission at no extra cost to you.