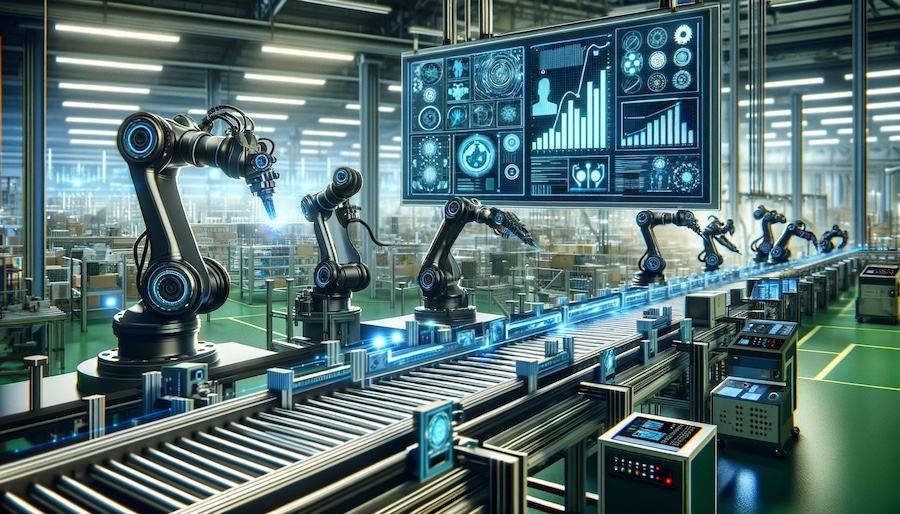

In the rapidly evolving landscape of manufacturing, industrial AI visual inspection stands at the forefront of technological advancements. This transformative approach harnesses the power of artificial intelligence to enhance the efficiency and accuracy of quality checks in industrial settings. By employing advanced image processing and machine learning algorithms, AI visual inspection systems have the capability to detect defects and anomalies with unprecedented precision.

The integration of AI in industrial processes is not merely a trend but a necessity. As industries strive for higher quality standards and cost-efficiency, industrial AI visual inspection emerges as a game-changer. In this article, we delve deep into the nuances of this technology, exploring its benefits, challenges, and the future it holds for industries worldwide.

What is Industrial AI Visual Inspection?

Industrial AI visual inspection refers to the application of artificial intelligence technologies to automate and enhance the process of inspecting products for defects or quality issues. Unlike traditional methods that rely heavily on human operators, AI-driven inspection systems utilize deep learning models to analyze images of products and detect defects with remarkable accuracy.

How It Works

The process begins with the collection of images using high-resolution cameras installed along the production line. These images are then processed by AI algorithms that identify patterns and deviations from predefined quality standards. By learning from vast datasets, these systems continuously improve their detection capabilities, ensuring consistent and reliable results.

Benefits of AI Visual Inspection in Industry

Implementing industrial AI visual inspection offers numerous advantages to manufacturing processes. One of the primary benefits is the significant reduction in inspection time. AI systems operate at high speed, far surpassing human inspection rates. This efficiency translates to increased production throughput and reduced operational costs.

Improved Accuracy and Consistency

AI visual inspection systems excel in accuracy, minimizing human error and ensuring consistent quality checks. By eliminating subjective judgments, these systems provide reliable and unbiased results, enhancing overall product quality.

Cost Efficiency

The automation of inspection processes leads to cost savings by reducing the need for manual labor. Additionally, early defect detection minimizes waste and rework, further contributing to cost-effectiveness.

Challenges in Implementing AI Visual Inspection

While the advantages are compelling, the implementation of industrial AI visual inspection is not without challenges. One major hurdle is the initial setup cost, which can be substantial. However, the long-term benefits often outweigh these initial investments.

Integration with Existing Systems

Integrating AI inspection systems with existing manufacturing processes requires careful planning and execution. Compatibility issues may arise, necessitating modifications to ensure seamless operation.

Data Quality and Management

The effectiveness of AI visual inspection systems heavily relies on the quality of data used for training. Poor quality data can lead to inaccurate results, highlighting the importance of robust data management practices.

The Future of AI Visual Inspection

The future of industrial AI visual inspection is promising, with continuous advancements in AI and machine learning technologies driving innovation. As these systems become more sophisticated, we can expect even greater accuracy and efficiency in quality checks.

Integration with IoT

The integration of AI visual inspection with the Internet of Things (IoT) opens up new possibilities for real-time monitoring and predictive maintenance. IoT-enabled devices can provide valuable data that enhances the capabilities of AI inspection systems.

Expansion Across Industries

While currently prominent in manufacturing, AI visual inspection is poised to expand into other industries such as healthcare, automotive, and electronics, where precision and reliability are paramount.

Conclusion

In conclusion, industrial AI visual inspection is a pivotal innovation in the quest for improved quality assurance in manufacturing. By automating and enhancing the inspection process, AI technology not only improves efficiency and accuracy but also offers substantial cost savings. As industries continue to embrace digital transformation, AI visual inspection will undoubtedly play a crucial role in shaping the future of quality assurance.

For more insights into AI-driven quality assurance solutions, visit automated visual quality checks and quality prediction using AI on Qualitech’s website. Additionally, explore how AI is making strides in AI tools for life science quality manufacturing.

FAQ

What industries benefit most from AI visual inspection?

Industries such as manufacturing, automotive, electronics, and healthcare benefit significantly from AI visual inspection due to their high demand for precision and efficiency.

How does AI improve inspection accuracy?

AI improves inspection accuracy by utilizing machine learning algorithms to analyze images and detect defects with high precision, reducing human error and providing consistent results.

What are the cost implications of implementing AI visual inspection?

While the initial setup costs can be high, the long-term savings from increased efficiency, reduced labor costs, and minimized waste make AI visual inspection a cost-effective solution for many industries.

This article contains affiliate links. We may earn a commission at no extra cost to you.