In the ever-evolving landscape of artificial intelligence (AI), the role of AI in visual inspection has become increasingly significant. Among the various tools available, Pytorch AI visual inspection stands out for its ability to enhance quality control processes. As industries strive to maintain high standards, integrating AI-driven solutions has become more crucial than ever. This article delves into how Pytorch AI is transforming visual inspection and improving quality assurance across sectors.

What is Pytorch AI Visual Inspection?

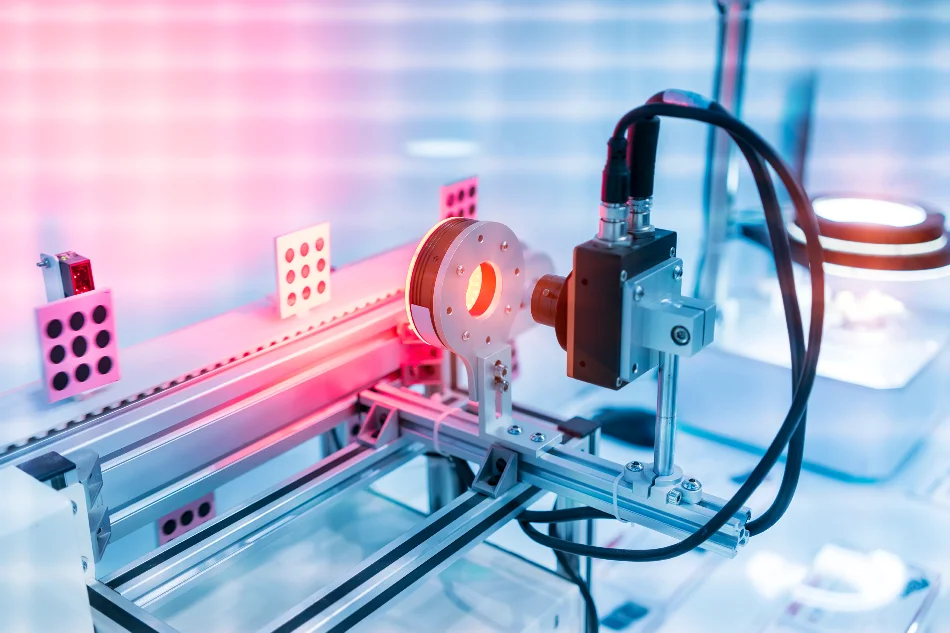

Pytorch AI visual inspection involves utilizing the Pytorch framework to develop AI models that can analyze visual data. This process is essential for identifying defects, inconsistencies, and other issues in products during manufacturing. By leveraging deep learning techniques, this approach enhances the accuracy and efficiency of quality control.

Why Choose Pytorch for AI Visual Inspection?

The choice of Pytorch for AI visual inspection is driven by its flexibility, ease of use, and strong community support. Pytorch offers dynamic computation graphs, allowing for more intuitive model building and debugging. Its simplicity makes it accessible to both beginners and experts, fostering innovation and rapid development in AI applications.

Benefits of Using Pytorch in Visual Inspection

- Flexibility: Pytorch’s dynamic nature allows for real-time modifications and adjustments, catering to specific inspection needs.

- Community Support: With a vast community, users can access a wealth of resources, tutorials, and forums to enhance their projects.

- Integration: Pytorch integrates seamlessly with other tools and platforms, ensuring a smooth workflow.

Implementing Pytorch AI in Industry QA

Implementation of Pytorch AI in AI Camera Systems is transforming traditional quality assurance practices. By automating visual inspection, companies can reduce human error and improve precision. This shift not only enhances product quality but also optimizes resource allocation.

Steps for Successful Implementation

- Identify key areas where visual inspection can be automated.

- Develop AI models using Pytorch tailored to specific inspection tasks.

- Integrate these models into existing production lines for real-time analysis.

- Continuously monitor and refine models to adapt to changing requirements.

Challenges Faced in Pytorch AI Visual Inspection

While the benefits are substantial, challenges such as data quality, model training, and cost can hinder implementation. Addressing these challenges requires strategic planning and investment in the right technologies.

Overcoming Data Quality Issues

Ensuring high-quality data is crucial for effective model training. Implementing robust data collection and preprocessing techniques can mitigate these issues. Companies can explore Reducing False Positives to enhance data accuracy.

Future of Pytorch AI Visual Inspection

The future of Pytorch AI visual inspection looks promising, with advancements in unsupervised learning and real-time analysis. Continuous development in Unsupervised Learning will pave the way for more autonomous and intelligent inspection systems.

Trends to Watch

- Increased use of cloud-based solutions for scalable AI deployments.

- Integration of AI with IoT for enhanced data collection and analysis.

- Advancements in automating visual asset inspection.

Conclusion

In conclusion, Pytorch AI visual inspection is reshaping the landscape of quality control. By embracing this technology, industries can achieve unprecedented levels of accuracy and efficiency. As AI continues to evolve, its role in quality assurance will only grow, offering new opportunities and challenges.

FAQs

What industries benefit the most from Pytorch AI visual inspection?

Industries such as manufacturing, automotive, and electronics greatly benefit from AI visual inspection due to the high demand for precision and quality.

How does Pytorch differ from other AI frameworks?

Pytorch stands out for its dynamic computation graphs and ease of use, making it an ideal choice for developing flexible and complex AI models.

Can Pytorch AI visual inspection reduce operational costs?

Yes, by automating inspection processes, companies can reduce labor costs, minimize errors, and enhance overall operational efficiency. Learn more about this in the ROI of AI Visual Inspection Systems.

This article contains affiliate links. We may earn a commission at no extra cost to you.