In the modern era of industry and manufacturing, ensuring product quality is paramount. One of the cutting-edge approaches enhancing quality control is semantic segmentation in inspection. This technique not only boosts efficiency but also ensures higher accuracy in identifying defects. In this article, we will delve into the world of semantic segmentation, its applications in inspections, and its potential impact on various industries.

What is Semantic Segmentation?

Semantic segmentation is a process in artificial intelligence (AI) that involves classifying each pixel in an image into a predefined category. Unlike traditional image processing methods, semantic segmentation provides a detailed understanding of the visual content by distinguishing different objects within an image. This level of detail is crucial for precise inspections.

The Role of Semantic Segmentation in Inspections

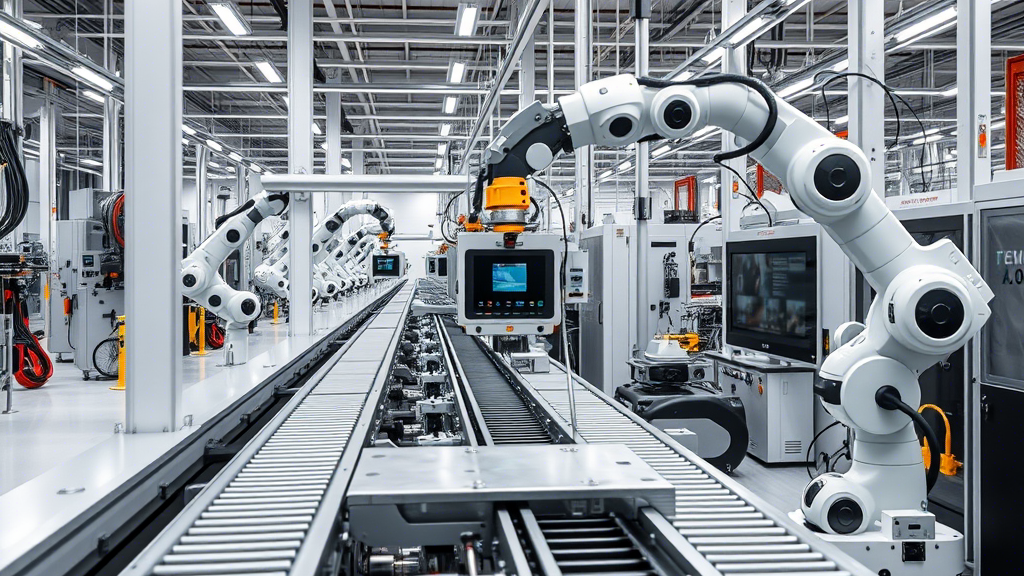

Applying semantic segmentation in inspection processes revolutionizes how industries monitor and maintain product quality. By categorizing every pixel, this method allows for a comprehensive analysis, ensuring that even the smallest defects are detected. This is particularly beneficial in industries where precision is critical, such as electronics and automotive manufacturing.

Advantages of Using Semantic Segmentation

Several advantages come with using semantic segmentation in inspection:

- Accuracy: It provides a high level of accuracy in detecting defects.

- Efficiency: It speeds up the inspection process, reducing the time and resources needed.

- Consistency: It ensures consistent quality checks, minimizing human error.

Applications Across Various Industries

The applications of semantic segmentation in inspection are vast and varied. Let’s explore how different industries benefit from this technology:

Electronics Manufacturing

In electronics, precision is non-negotiable. Object detection AI plays a crucial role in identifying minute defects in circuit boards and components, ensuring that only flawless products reach consumers.

Automotive Industry

The automotive sector utilizes semantic segmentation to inspect parts and assemblies. This technology ensures that vehicles meet safety and quality standards, which is crucial for brand reputation and consumer safety.

Textile Industry

In textiles, detecting flaws in fabric patterns or stitching was traditionally labor-intensive. Now, with AI and segmentation, these imperfections are identified swiftly and accurately. Technologies like wrinkle detection AI are transforming quality checks in this sector.

Challenges in Implementing Semantic Segmentation

Despite its benefits, implementing semantic segmentation in inspection does come with challenges. It requires substantial computational resources and expertise in machine learning. Additionally, creating accurate models demands access to high-quality, labeled datasets.

Overcoming Implementation Hurdles

To overcome these challenges, companies often partner with AI specialists or invest in training their workforce. Furthermore, leveraging unsupervised learning techniques can reduce the dependency on large labeled datasets, as seen in unsupervised learning strategies.

Future of Semantic Segmentation in Quality Control

The future of semantic segmentation in inspection looks promising. With continuous advancements in AI, we expect even more precise and efficient inspection systems. This evolution will likely lead to broader adoption across different sectors, further enhancing product quality and operational efficiency.

Integration with IoT and Smart Manufacturing

Integrating semantic segmentation with IoT devices and smart manufacturing systems will provide real-time data analysis and decision-making capabilities. This synergy will enable more responsive and adaptive manufacturing processes.

Expanding to New Industries

As technology becomes more accessible, we anticipate its adoption in new fields, such as agriculture and healthcare, where precise inspection and monitoring are equally critical.

Conclusion

In conclusion, semantic segmentation in inspection is transforming the landscape of quality control. By enhancing accuracy, efficiency, and consistency, it offers industries a powerful tool to maintain high standards. As technology continues to evolve, its role in inspections will only become more significant, promising a future where quality is assured with greater confidence.

FAQs

What is semantic segmentation in inspection?

Semantic segmentation in inspection refers to the use of AI to classify and analyze each pixel in an image, allowing for precise defect detection in various inspection processes.

Why is semantic segmentation important in quality control?

It provides detailed analysis, ensuring accurate and consistent defect detection, reducing human error, and increasing efficiency in the inspection process.

What are the challenges of using semantic segmentation?

Challenges include the need for significant computational resources, expertise in machine learning, and access to high-quality labeled datasets.

For more insights into the benefits of visual inspection in manufacturing, you can visit IBM’s insights on visual inspection.

This article contains affiliate links. We may earn a commission at no extra cost to you.