In today’s rapidly advancing technological landscape, the integration of unsupervised learning and visual inspection is revolutionizing the way industries approach quality control. At the forefront of this innovation is the concept of unsupervised learning visual inspection, which offers a fresh perspective on enhancing product quality and efficiency. This article delves into the intricacies of this cutting-edge technology, exploring its applications, benefits, and the promising future it holds for industry quality assurance.

Understanding Unsupervised Learning

Unsupervised learning is a branch of machine learning where algorithms are tasked with identifying patterns in data without any prior labels or training. This approach contrasts with supervised learning, which relies on labeled data. Unsupervised learning is particularly useful in scenarios where acquiring labeled data is challenging or impractical.

Key Concepts of Unsupervised Learning

- Clustering: Grouping data points based on similarities.

- Dimensionality Reduction: Simplifying data while maintaining its essential characteristics.

- Anomaly Detection: Identifying data points that deviate significantly from the norm.

The Role of Visual Inspection in Industry

Visual inspection is a critical component of quality control processes across various industries. Traditionally, it involves manual examination of products to identify defects or inconsistencies. However, with the advent of artificial intelligence and machine learning, visual inspection is undergoing a significant transformation.

Traditional vs. AI-Powered Visual Inspection

While traditional visual inspection methods rely heavily on human expertise, AI-powered systems offer numerous advantages, including increased accuracy, speed, and scalability. By leveraging machine learning algorithms, these systems can analyze vast amounts of visual data and detect defects with remarkable precision.

The Intersection of Unsupervised Learning and Visual Inspection

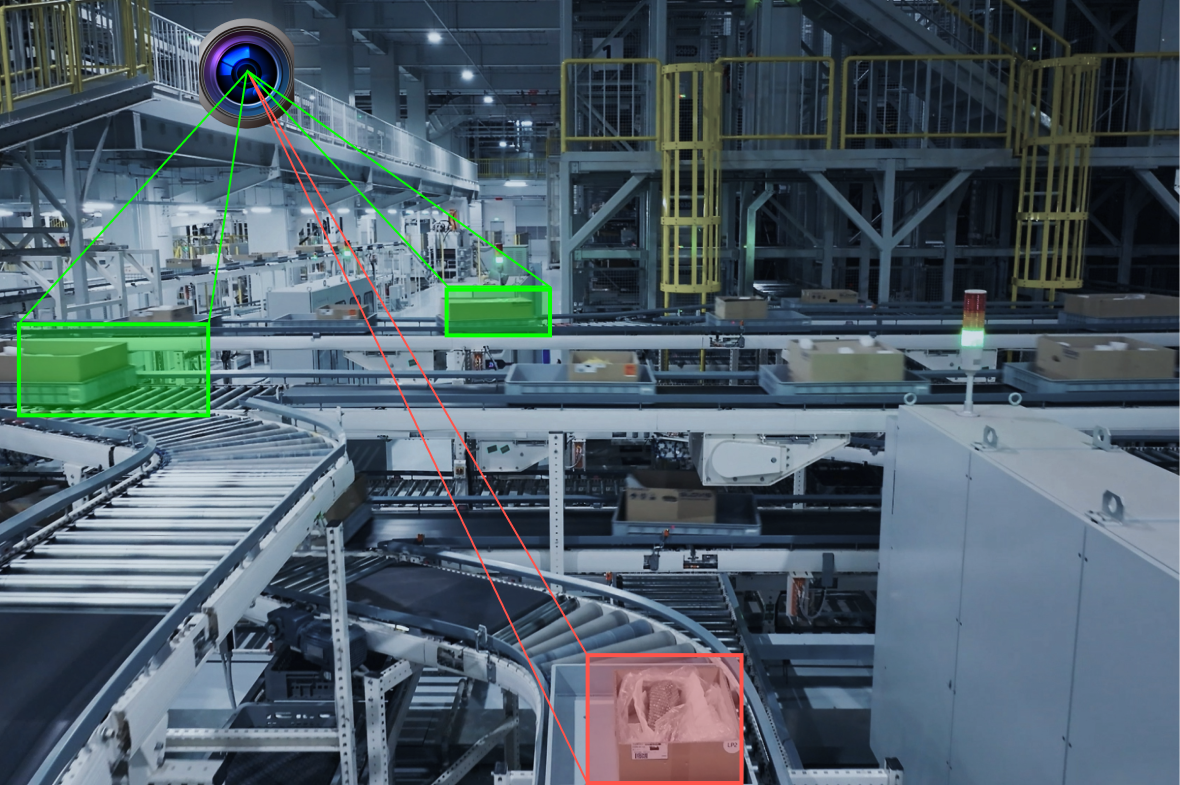

The fusion of unsupervised learning with visual inspection represents a paradigm shift in quality control. This approach enables the automated identification of defects and anomalies, even in the absence of labeled data. As a result, industries can achieve higher levels of efficiency and accuracy in their quality assurance processes.

Applications of Unsupervised Learning Visual Inspection

From manufacturing to healthcare, unsupervised learning visual inspection is making its mark across diverse sectors. Some notable applications include:

- Manufacturing: Ensuring product consistency and detecting defects in real-time.

- Healthcare: Analyzing medical images for early detection of abnormalities.

- Automotive: Inspecting vehicle components for quality assurance.

Benefits of Unsupervised Learning Visual Inspection

Integrating unsupervised learning with visual inspection offers several advantages, including:

- Improved Accuracy: Enhanced defect detection capabilities.

- Cost Efficiency: Reduced reliance on manual inspection.

- Scalability: Ability to handle large volumes of data.

Challenges and Considerations

While the potential of unsupervised learning visual inspection is immense, it is not without challenges. Some considerations include:

- Data Quality: Ensuring high-quality input data is crucial for accurate results.

- Algorithm Complexity: Balancing complexity and interpretability.

- Integration: Seamlessly incorporating new technology into existing workflows.

The Future of Unsupervised Learning Visual Inspection

As technology continues to evolve, the future of unsupervised learning visual inspection looks promising. With ongoing advancements in AI and machine learning, industries can expect even greater improvements in quality control processes. The potential for innovation is vast, and the impact on efficiency and productivity is likely to be profound.

Real-World Examples and Case Studies

Several companies have already embraced unsupervised learning visual inspection with remarkable success. For instance, the automotive industry has leveraged this technology to enhance vehicle safety and quality. Similarly, in manufacturing, companies are optimizing production lines by automating defect detection processes.

Integrating Unsupervised Learning Visual Inspection into Your Workflow

For businesses looking to integrate unsupervised learning visual inspection into their quality control processes, several steps can be taken:

- Assessment: Evaluate current inspection methods and identify areas for improvement.

- Technology Selection: Choose the right tools and platforms for your specific needs.

- Implementation: Seamlessly integrate new technology into existing workflows.

For more insights on seamless integration, you can visit this external link.

Conclusion

The integration of unsupervised learning and visual inspection marks a new era in quality control, offering a wealth of opportunities for industries to enhance their processes. By leveraging the power of AI and machine learning, businesses can achieve unprecedented levels of efficiency, accuracy, and cost savings. As we look to the future, the potential for innovation in this field is limitless, promising a brighter and more efficient tomorrow.

FAQs

What is unsupervised learning visual inspection?

Unsupervised learning visual inspection refers to the use of machine learning algorithms to analyze and detect patterns in visual data without labeled inputs, enhancing quality control processes.

How does unsupervised learning differ from supervised learning?

Unlike supervised learning, which relies on labeled data, unsupervised learning identifies patterns and anomalies in data without prior labels, making it ideal for complex or unlabeled datasets.

What industries benefit from unsupervised learning visual inspection?

Industries such as manufacturing, healthcare, and automotive benefit from unsupervised learning visual inspection by improving accuracy, efficiency, and scalability in quality control processes.

This article contains affiliate links. We may earn a commission at no extra cost to you.